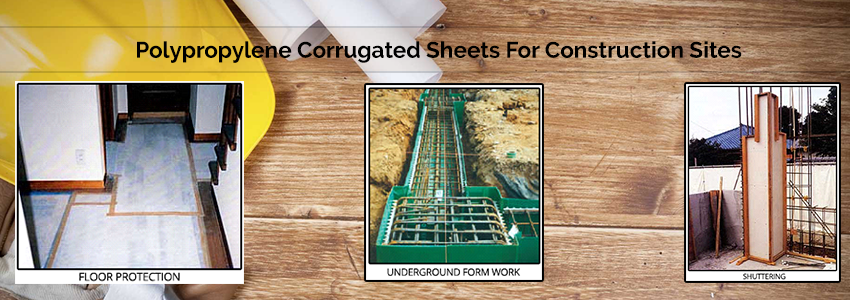

Polypropylene Corrugated Sheets For Construction Sites

1. Floor protection by Corpac plastic corrugated sheets

At construction sites when the floor has been finished there are several works like plastering, electrical work, painting and false ceiling goes on to be finished.

Flooring needs a protection against damage due to movement, tools falling, other materials dropping on floor. Conventionally polythene film is laid on the floor and POP is put on this with a layer of at least ½”.

We recommend using Corrugated Plastic Sheets which are light weight and very easy to lay, thus less labor cost. It is sturdier and neater than conventional materials. After use, it does not create trash to be cleared. Over and above Corpac sheets can be removed and reused in other areas for floor protection. Multi-time use gives big saving to a builder. Looking into the cost of flooring versus the cost of the sheet it can be even left in the place and can be removed at the time of Handover of Area to the customer. The customer gets crisp and fresh flooring.

If a building contracture chooses any other material or product to protect the floor apart from PP corrugated sheets, it may cost them higher then it because they don’t even pay higher, even they can’t use that material multiple times. It may be weightier than PP corrugated Sheets and that would also require more time and labor to handle it. So better to choose Corpac Plastic Corrugated Sheets to save money and time to protect floors at construction sites.

2. Corpac plastic corrugated sheets for underground Form Work

Grouting can help to arrest water leakages at underground work of construction sites. But in the absence of a PP sheets coverage the entire surface (outer or inner) of the tunnel with an effective waterproof system, leakages will keep sprouting at the new locations of the concrete structure.

After setting up the PP sheets at underground work, the concrete structure will be protected from water membrane and there will be no chance for leakages. So it is better to choose Polypropylene Corrugated Sheets for safe & strong underground formwork because if roots are strong only then the big tree can survive.

By use of PP Corrugated Sheets in underground Form Work labor cost and time drastically comes down. No extra digging for placement of shuttering has to be done, no shuttering material is required and finally, no effort has to be put to take out shuttering work. Sheets are left there after concrete casting; this also gives a protection to concrete against corrosive material in the soil. Overall time and money both are saved due to this application.

3. Polypropylene corrugated sheets as shuttering material

The column framework systems now available in Polypropylene Corrugated Sheets are modular and allow quickly assemble and correction on the site while minimizing labor and crane time too.

Polypropylene Sheets are easier to handle than steel aluminum and even cardboard (also reasonable & recyclable) and have a variety of internal face surfaces depending on the concrete finish required. Innovations have led to adjustable, reusable column forms which can be clamped on-site to give different column size.

In conventional shuttering materials, waterproof plywood is used as inside liner which goes bad after 8/10 use. PP Corrugated sheet can be a very good and economical solution as replacement of plywood which is comparatively costly, and these sheets are totally waterproof.

4. Water Membrane protection

In underground construction water membrane has to be put on outside wall. Water membrane is very weak in strength and can be pierced and damaged very easily. These sheets are used to protect the water membrane to avoid any type of water seepage to the inside of a wall.

Latest Post

.jpg)

Why Polycarbonate is opted for Construction?

Oct 29, 2021

Corrugated Plastic Sheets for Floor Protection

Mar 03, 2021

The Disadvantages of Corrugated Plastic

Jan 22, 2021

Polycarbonate vs. Glass: What’s the Best Choice?

Dec 26, 2020

.jpg)

Benefits of Corrugated Sheets & its Types

Nov 25, 2020